PRODUCTION TECHNOLOGIES

ZERO TOUCH ROBOTIC TECHNOLOGY

ImplatechOne Implant is at the forefront of technological advancement, delivering premium products to users worldwide. Our state-of-the-art robotic technology provides precise etched implant surface without human intervention by creating a consistently uniform texture.

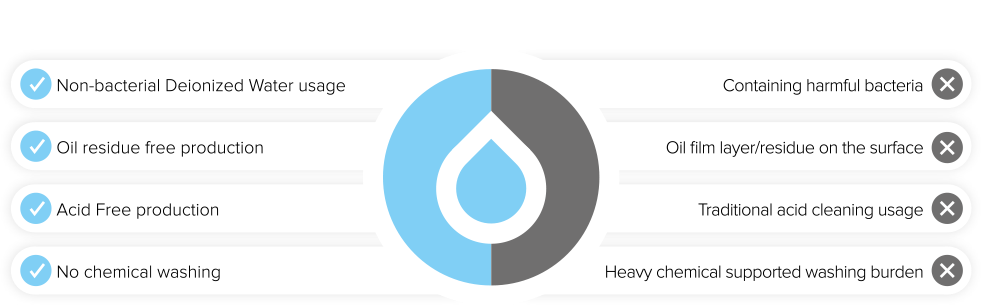

ImplatechOne is one of the very few manufacturers to employ Deionised Water Technology as a coolant in the CNC production of implant components, a revolutionary departure from the traditional standard of industrial oil usage.

This innovative approach is not merely a preference but a cornerstone of ImplatechOne’s unparalleled expertise. Traditional CNC processes heavily rely on industrial cooling oils to regulate the temperature of cutting tools. Nevertheless, these oils deposit a residual film on finished parts, fostering an environment conducive to anaerobic bacteria growth. Moreover, upon depletion, they become a significant industrial waste burden. To clean these residual oils from the surface it is a must to use highly concentrated chemicals in washing processes, which are again creating damages and residuals on the surface that leads to another industrial waste burden.

Bacteria growth on the oil-machined and sandblasted implants was higher than the implants only machined in oil (p value 0.014) and DI water (p value 0.002).

Cytotoxicity experiments also showed ~ 5% higher cell concentration on the DI-water-machined implants than the oil-machined implants and ~ 10% higher than the oil-machined/sandblasted implants.

University of Florida & Virginia – USA 2022